Industrial Induction Heating Coil Repairing Services

MOQ : 1 Thousand, Thousand

Industrial Induction Heating Coil Repairing Services Trade Information

- Minimum Order Quantity

- 1 Thousand, Thousand

- Main Domestic Market

- Central India

About Industrial Induction Heating Coil Repairing Services

Expert Repair Solutions for Customized Induction Heating Coils

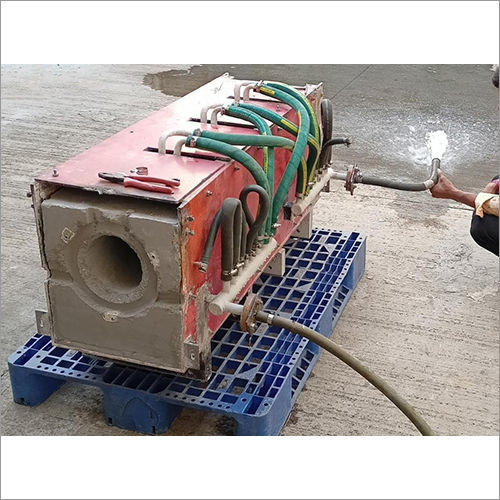

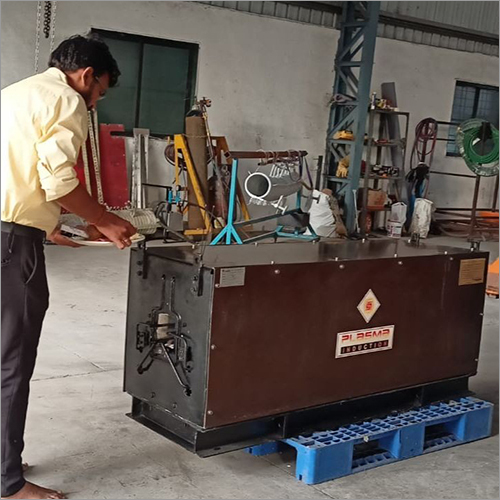

We offer specialized repairs for a variety of induction heating coils, tailored to meet your specific requirements. Whether your coils are copper, aluminum, or a different material, our engineers use cutting-edge techniques and precision tools to restore them to optimal condition. Both on-site and workshop-based repair options are available, ensuring convenience and flexibility for our clients across the automotive, aerospace, and metal processing sectors.

Efficient and Reliable Coil Maintenance with Advanced Techniques

Our service process includes coil rewinding, insulation replacement, hard soldering, and cooling channel de-choking to address all common coil failures. Each project is completed with comprehensive performance testing and final inspection, so you can depend on your coils for superior durability and efficiency. We accommodate urgent requests with 24/7 emergency support, ensuring minimal disruption to your operations.

FAQ's of Industrial Induction Heating Coil Repairing Services:

Q: How are induction heating coils repaired through your services?

A: We repair induction heating coils using advanced techniques, including rewinding the coil, replacing insulation, hard soldering, and de-choking cooling channels. Our technicians employ precise calibration tools to ensure each coil meets industry standards before it is returned to you.Q: What types of induction heating coils can you repair?

A: We can repair a wide range of coil types, including those made from copper, aluminum, and other materials. The coils can be customized as per your specific application and requirements, with the ability to handle coils up to 1500 mm in diameter.Q: When and where are your repair services available?

A: Our industrial induction heating coil repair services are available both on-site at your facility and off-site at our workshop. We provide flexible scheduling, as well as 24/7 emergency breakdown support on request, to accommodate your operational needs.Q: What does the typical repair process involve?

A: The repair process entails a thorough inspection, followed by coil rewinding, insulation replacement, hard soldering, and cleaning of cooling channels as required. After repairs, coils undergo comprehensive performance testing and a final quality inspection.Q: How long does a typical coil repair take?

A: Standard repairs are completed within 3 to 7 working days, depending on the coil's size and degree of damage. Custom orders or particularly complex repairs may require additional time, which will be communicated at the outset.Q: What benefits do your induction heating coil repairing services offer?

A: By choosing our services, you benefit from improved coil longevity, reduced equipment downtime, and enhanced operational efficiency. Our quality assurance process ensures that each repaired coil meets strict industry standards, with optional warranty coverage for added peace of mind.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Induction Heating Coil Repairing Services Category

Industrial Induction Heating Coil Maintanance Services

Price 50000 INR

Minimum Order Quantity : 1 Thousand, Thousand

"We are dealing only local areas."

HARIOM INDUCTION SERVICES

GST : 27APWPK2530G1ZP

GST : 27APWPK2530G1ZP

Gat No. 357 25 U Turn Ind Hub, Chakan, Khed - 410501, Maharashtra, India

Phone :08071793858

|

|

HARIOM INDUCTION SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry